by Stephanie Palazzolo, managing editor

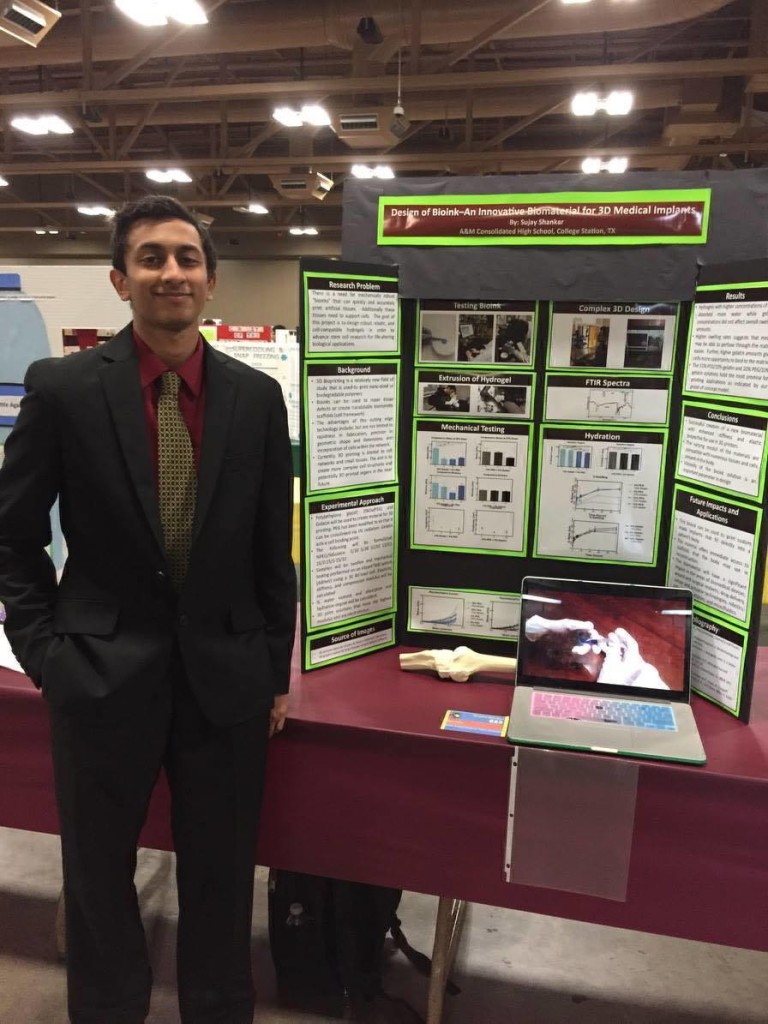

This upcoming May, junior Sujay Shankar will leave behind three AP tests for a week in sunny Phoenix, Arizona, where he will compete with his newly-created bioink in the Intel International Science and Engineering Fair, or Intel ISEF.

“I basically created this new material using different polymers that can be printed using a 3D printer,” Shankar said. “This material can be incorporated with cells from the human body, so if you have damaged tissues or damaged cartilage, you can inject or implant this material into your body to take the place of that damaged tissue for some time. It will slowly degrade and new tissue will regrow in its place.”

Shankar recently competed in the Austin Regional Science Festival, where he was one out of six to win “Best in Fair” and move on to Intel ISEF, thanks to the innovative nature of his new bioink.

This “repair-and-regenerate” material is the product of months of research, as Shankar has been working on the project since September 2015. One cause of this long development period was the material’s strict requirements.

“[It needs to be] robust, stiff and cell compatible,” Shankar said. “We’ve grown a lot of cell tests on those, so we incorporate cells and see if they thrive. We also do mechanical studies just to show strength because you don’t want it to be weak, but you [also] want it to be stretchable.”

This material combines polyethylene glycol, a nontoxic synthetic polymer found in humans, and gelatin, a natural polymer, in addition to several other elements. With polyethylene glycol’s stiffness and gelatin’s cell-friendly nature, Shankar hopes that his creation is reaching a nice balance of rigidity and flexibility.

Perhaps one of the most important aspects of this bioink was its ability to be made with a 3D printer, allowing for quick and easy production.

“Not everything can be printed by a 3D printer,” Shankar said. “So you have to make sure the material is not too viscous or too thick when it comes out of the [printer] nozzle, [but] you don’t want it to be too ‘liquidy’ or else it will just flow. [It needs to be] this viscous syrup material that you can print out.”

Shankar’s research consisted of a lot of trial and error; luckily, Dr. Akhilesh Gaharwar, a biomedical assistant professor at Texas A&M, provided the resources for him to create the bioink.

“I observed for a while [in the lab] what people were doing, and after that I came up with a project,” Shankar said. “The graduate students that work there and some of the undergrads, they’re also making materials of their own for different purposes. But the common goal is similar between all of us because we all want to make something new.”

However, as a high schooler working in a college laboratory up to four times a week, Shankar struggled with balancing school work and lab work.

“When you make new material or part of a new material, you have to test it the next day or keep it for a certain amount of time in water, and it’s hard with school to [find the time] to go the lab,” Shankar said. “I have 4th and 5th off, so I work [in the lab] for an hour, an hour and fifteen minutes. I run some tests, I make some [more materials.]”

Shankar is looking forward to the next stage of competition and to continuing biomedical research in college, but for now, his main goal is to improve his current material and to work through seemingly unending obstacles.

“Sometimes I add something that doesn’t even make a material — I’ll add a polymer and it’ll just turn into a liquid,” Shankar said. “You just have to keep on experimenting and figure out what you’ll do next.”