by Vi Burgess, staff reporter

From cell phones to sliding doors, parts of the world first imagined by “Star Trek” are slowly starting to appear in present-day life. Over the summer, Consol made a push to go even further towards the final frontier with the addition of a 3-D printer that can create tangible models and prototypes from a virtual platform on a computer.

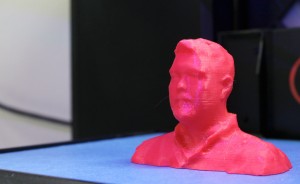

The Makerbot 2X, affectionately nicknamed “Felix,” resides in Computer Maintenance teacher Bart Taylor’s classroom. It prints thin layers of PLA (polylactic acid) plastics to build models. Typically, each piece can take anywhere from 12 to 34 hours to print on an approximately 10 x 8 x 8 inch scale.

“It’s really limitless on what we can do; it’s just what the students want to make and try, and while they’re doing these projects and printing, we’re learning how to support and maintain [the printer],” Taylor said.

Taylor purchased Felix with a large grant he received at the end of the last school year.

“We polled the school, because this was just money that we could use; a majority of people said [we] could use a 3-D printer,” Taylor said. “I had wanted [a printer] for a while, and I had been trying to buy one, so it was a great opportunity for us to get one in the [Computer Maintenance] classes.”

Taylor and his students are currently using the printer to print “fun things”, such as an 8×8 inch selfie model of Taylor himself, as well as more practical objects like prototypes for Robotics. Senior Sam Suh, a longtime member of the Computer Maintenance program, has worked with Felix more than any other student.

“I originally wanted to print just little things to decorate the room with, like little 3-D models of video game characters or something like that, like Mario and Luigi,” Suh said.

Other students and teachers, with promised invitations to test it out, are already excited. Many have begun dreaming and designing possibilities for printed models.

“Mostly, everyone thinks it’s pretty awesome,” Suh said. “People were finding things all over the place like chess sets, phone cases, everything, even chairs, toys, stuff for kids. They really wanted to print everything they could imagine.”

Already, Taylor and his students have begun troubleshooting and discovering new aspects of the printer. “The basic setup was hard, and the test prints didn’t come out right; it was a good trial and error,” Taylor said. “The directions were lacking. There was a knob [on the printer to level it] so we tried to level it manually and then we realized that there’s some laser calibrations [instead]; later, we found out there’s a webcam on the printer too.”

Even the models that do make it through the long queue to print have flaws, proving that the technology still has a long way to go.

“It just bothered me that there were little frays and plastic chunks hanging off of models and it made [the models] look very unrefined, because there would just be little strings of sinews leftover from the plastic,” Suh said. “I went a little more extreme and took a soldering iron, pushed it to 180, and just literally melted the plastics back together.”

However, Taylor and his students are eager to experiment and play with Felix the 3-D printer more, as they continue to print and repair it.

“There’s just more things to discover; there’s glow-in-the-dark plastics and photoreactive plastics to print, there’s flexible plastics I want to buy [as well],” Taylor said. “There’s a lot of fun applications I think you could do with it.”